Hi MM, I used a 'burst' method of driving 200KHz and 30KHz transducers. The transducer pulse generator was from a square wave osc, tunable over a narrow range in order to get the optimum power out from the transducer.

PGA460 Ultrasonic Signal Processor and Transducer Driver 1 1 Features. Chip ultrasonic transducer driver and signal conditioner with an advanced DSP core. Consisting of a low-noise amplifier followed by a programmable time-varying gain stage feeding into an ADC. The digitized signal is processed in the DSP.

PGA460 Ultrasonic Signal Processor and Transducer Driver 1 1 Features. Chip ultrasonic transducer driver and signal conditioner with an advanced DSP core. Consisting of a low-noise amplifier followed by a programmable time-varying gain stage feeding into an ADC. The digitized signal is processed in the DSP.

The pulse or burst width generator was adjustable from 100uSec thru 10mSec, this enabled a level of power control in the acoustic pulse. The transducer driver stage was a NPN power transistor driving a 1:3 or 1:5 transformer at 30KHz or 200KHz respectively, supply voltage 12V or 24V depending upon the required acoustic power. My product applications were for hydro-graphic depth echo sounders, working in water depths of 0.5mtr upto 400mres. E Is you application bio-diesel.?

Hi Eric, Isn't the number of cycles (burst) of 40khz determined by the length of the ON pulse? A 20ms pulse will have more cycles that a 2ms one (10 times more).

The size of the Burst is directly related to the duty cycle. In order to increase the burst time, we need an amplifier that will take more power. Currently I can't get past a duty cycle of 1% without smoking the heatsinked Fet.

EG: 5ms ON and 500mx OFF. As I mentioned before, I dip all transducers to find their exact resonant TX frequencies and their band pass. Then I program the CPU to change frequency over the band pass. If the BP is say 2khz wide, I will step the frequency up by 100hz every few seconds. That way I send multiple bursts to 20 different frequency locations, of which a few should be more effective in ringing the wafer. What do you think? I built a cat scarer at my last house.

I didn't bother with trying to tune to the ultrasonic horn I had. I drove the secondary of a toroidal mains transformer using a low voltage drive at ~41KHz and used the primary straight across the piezo horn. Maybe not the most efficient, but it worked effectively and gave quite a nip when touched. What surprised me most was the frequency response of a 6.0.6-240VAC cheapo toroid was at such a frequency. It solved my cat problem BTW with me having to suffer the loud click when the device first powered the horn. I could have resolved this with a bit of signal/startup logic but never bothered in the end.

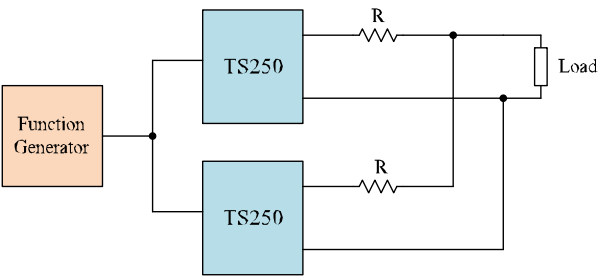

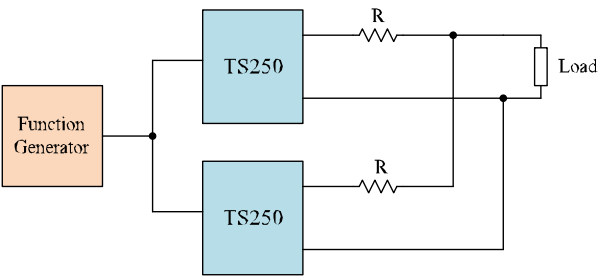

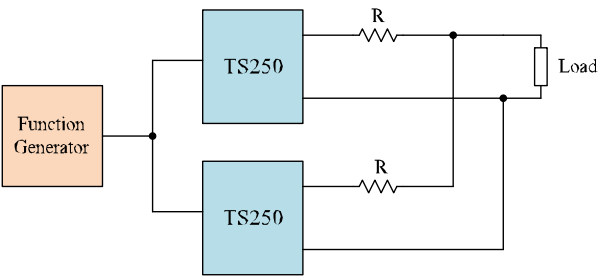

It all depends on how you want to drive the transducer i.e. The application: - It appears that you can drive at resonance or anti-resonance which indeed does make it pretty similar to how you would use a crystal in an oscillator. The graph above is taken from interesting website. I can't determine from your question what application you have but, from the (in the other question) to the type of transducers you use it seems you will be series resonating the transducer and this means it has low impedance at resonance due to L and C being in series. This means that the type of control circuit will look like this: - Taken from and this site also has some very useful information and an ebay link to a cheap one: - But, if you are still intent on building your own you can use the series resistance method to generate a feedback signal to the front-end of a power amplifier.

...">Ultrasonic Transducer Driver Amplifiers(23.12.2018)

Ultrasonic Transducer Driver Amplifiers Rating: 6,5/10 7081 votesHi MM, I used a 'burst' method of driving 200KHz and 30KHz transducers. The transducer pulse generator was from a square wave osc, tunable over a narrow range in order to get the optimum power out from the transducer.

PGA460 Ultrasonic Signal Processor and Transducer Driver 1 1 Features. Chip ultrasonic transducer driver and signal conditioner with an advanced DSP core. Consisting of a low-noise amplifier followed by a programmable time-varying gain stage feeding into an ADC. The digitized signal is processed in the DSP.

PGA460 Ultrasonic Signal Processor and Transducer Driver 1 1 Features. Chip ultrasonic transducer driver and signal conditioner with an advanced DSP core. Consisting of a low-noise amplifier followed by a programmable time-varying gain stage feeding into an ADC. The digitized signal is processed in the DSP.

The pulse or burst width generator was adjustable from 100uSec thru 10mSec, this enabled a level of power control in the acoustic pulse. The transducer driver stage was a NPN power transistor driving a 1:3 or 1:5 transformer at 30KHz or 200KHz respectively, supply voltage 12V or 24V depending upon the required acoustic power. My product applications were for hydro-graphic depth echo sounders, working in water depths of 0.5mtr upto 400mres. E Is you application bio-diesel.?

Hi Eric, Isn't the number of cycles (burst) of 40khz determined by the length of the ON pulse? A 20ms pulse will have more cycles that a 2ms one (10 times more).

The size of the Burst is directly related to the duty cycle. In order to increase the burst time, we need an amplifier that will take more power. Currently I can't get past a duty cycle of 1% without smoking the heatsinked Fet.

EG: 5ms ON and 500mx OFF. As I mentioned before, I dip all transducers to find their exact resonant TX frequencies and their band pass. Then I program the CPU to change frequency over the band pass. If the BP is say 2khz wide, I will step the frequency up by 100hz every few seconds. That way I send multiple bursts to 20 different frequency locations, of which a few should be more effective in ringing the wafer. What do you think? I built a cat scarer at my last house.

I didn't bother with trying to tune to the ultrasonic horn I had. I drove the secondary of a toroidal mains transformer using a low voltage drive at ~41KHz and used the primary straight across the piezo horn. Maybe not the most efficient, but it worked effectively and gave quite a nip when touched. What surprised me most was the frequency response of a 6.0.6-240VAC cheapo toroid was at such a frequency. It solved my cat problem BTW with me having to suffer the loud click when the device first powered the horn. I could have resolved this with a bit of signal/startup logic but never bothered in the end.

It all depends on how you want to drive the transducer i.e. The application: - It appears that you can drive at resonance or anti-resonance which indeed does make it pretty similar to how you would use a crystal in an oscillator. The graph above is taken from interesting website. I can't determine from your question what application you have but, from the (in the other question) to the type of transducers you use it seems you will be series resonating the transducer and this means it has low impedance at resonance due to L and C being in series. This means that the type of control circuit will look like this: - Taken from and this site also has some very useful information and an ebay link to a cheap one: - But, if you are still intent on building your own you can use the series resistance method to generate a feedback signal to the front-end of a power amplifier.

...">Ultrasonic Transducer Driver Amplifiers(23.12.2018)

PGA460 Ultrasonic Signal Processor and Transducer Driver 1 1 Features. Chip ultrasonic transducer driver and signal conditioner with an advanced DSP core. Consisting of a low-noise amplifier followed by a programmable time-varying gain stage feeding into an ADC. The digitized signal is processed in the DSP.

PGA460 Ultrasonic Signal Processor and Transducer Driver 1 1 Features. Chip ultrasonic transducer driver and signal conditioner with an advanced DSP core. Consisting of a low-noise amplifier followed by a programmable time-varying gain stage feeding into an ADC. The digitized signal is processed in the DSP.